Introduction - Homebrewing beer for every budget. For people with a lot of time and faster.

Your own beer, imagine. Turning water into beer. There are those who have done it with wine, but it can also be done with beer. In this piece of text I want to give you step-by-step practical information to brew your own beer. No complicated theories with words that scare you off, but hands-on, ready-to-use information to make your own beer. Throughout this article you will also find the supplies to get started. You can spend as much money on it as your budget allows. You can make beer quickly and spend a little more time on it. Before I start with the 9 steps to making beer, I will explain 2 ways in which you can make your own beer.

The 9 Fundamental Steps in Brewing Beer

I'm going to mention the stages now, so I can refer back to them later in this beer brewing guide.

- The choice of beer style and ingredients

- The grain shot

- Mashing or making batter

- Rinsing the grain bed

- Boiling the wort

- Cooling the wort

- Fermenting the wort

- Cold stabilization or cold crashing

- Bottling and storage

But before we start with the 9 steps, some explanation.

Instant coffee or should I grind my own beans ?

That the article is not about coffee, you could have guessed. But the 2 ways to make beer can be compared to coffee. It is about saving time and simplicity. For me it does not detract from the quality. I already drank super tasty instant coffee and I also found coffee from home-ground coffee beans from Guatemala undrinkable. The 2 methods to make beer that I want to explain are:

- Making beer with a beer brewing kit with beer concentrate or malt extract

- All grain method: making craft beer with grains, possibly sugar, hops, yeast & possibly additives

Brewing beer with a beer brewing kit: beer concentrate or malt extract to make beer

Brewing beer with beer concentrate or malt extract is a simple and inexpensive way to brew high quality beer at home. Despite what some homebrewers say, brewing with beer concentrate or malt extract can produce great beer.

Let's say that with a beer package in extract or concentrate you make the first 6 steps of brewing beer very easy. With such a concentrate or extract you are already halfway in making beer and you have already eliminated the most time-consuming steps. The choice is yours whether you brew with a concentrate or extract.

With beer brewing kits (ingredients) you can also buy a beer kit (material you need) which contains all the material to process your beer kit into beer. A beer brewing kit is ideal to discover whether making beer is something for you. If you are bitten by the beer brewing bug, you can delve further and consider using the all grain method. With the all grain method for brewing beer, you can go in even more directions and set your own accents. A beer brewing kit with concentrate or extract can be compared to making art with 12 colored pencils, the all grain method is more like painting with a pallet where you can make countless color combinations yourself.

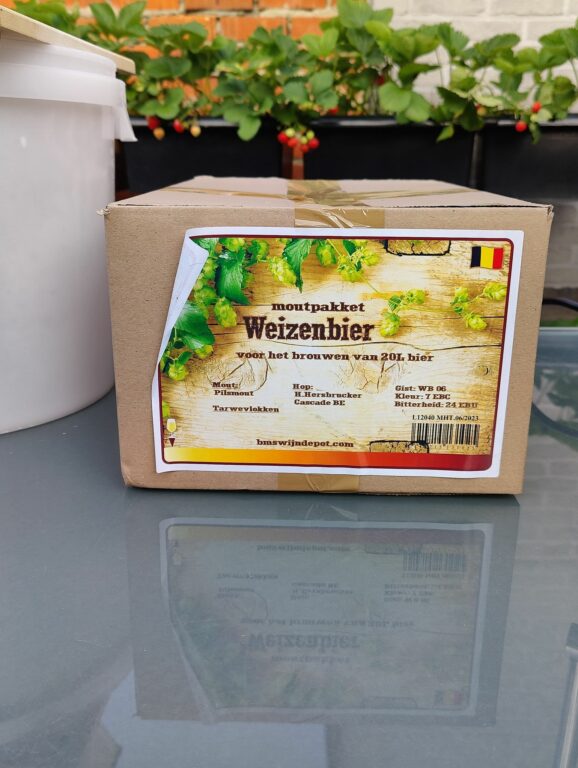

There are also all grain beer brewing kits or malt kits that contain malt, hops, yeast and additives to go through all 9 steps. They are interesting if you do not want to make all the choices yourself and still want to brew an original beer.

Brewing beer from grains, possibly sugar, hops, yeast & possibly additives (all grain method)

With just a piece of charcoal you can make a beautiful drawing. But with multiple colors, painting techniques, types of canvas, ... you can be very creative. I have that feeling a bit with all grain brewing. Not that it automatically makes your beer better, but you have so many more options. You also have more options to completely screw it up :) With a beer brewing kit extract or concentrate that I mentioned earlier you have less chance of mistakes even though you have to pay attention to that too.

In this article I will only discuss all grain or craft brewing with water, grain, hops, yeast and other additives. I will not discuss concentrate or extract brewing because usually the product description on the packaging tells you perfectly how to brew your beer.

Before I explain the 9 steps from water to beer, I will give you some introductory information for brewing all grain beer:

What equipment do you need to brew beer?

FYI: I brew beer with an automatic brew kettle with circulation pump. These days they are already quite cheap and very handy for brewing with grain. For 400-500 euros you have an automatic brew kettle that guides you through all the steps of brewing up to fermentation (step 7) without any problems. A brew kettle with a grain bag in it that you have to put on the electric or gas fire with all the 'risk of burning' that entails, I do not want that.

If you take the hobby seriously and you have the budget to buy an automatic brew kettle, then don't hesitate. If you want to see if brewing beer is really something for you and/or if you want to spend less money, then you should choose to brew from a concentrate (see above). With a 'starter set beer extra' with a plastic bucket and all measuring equipment for 75 euros you can make perfect beer. But for all grain brewing I would always recommend an automatic brew kettle.

My beer brewing equipment apart from the ingredients (water, malt, hops, yeast and additives) in an overview:

- A grain mill

- Grain collection bucket

- My automatic brew kettle, the Brewster Beacon (40 or 70 liter)

- A stirring paddle with holes

- Disinfection and cleaning products

- Puro oxi Puro Oxi 1kg Disinfection and cleaning of large surfaces

- Hydrogen peroxide 'P3-oxides rapid'

- My Grainfather rinse water heater. (you can also manually heat rinse water to temperature - usually 78 degrees)

- My Hanna pH tester for Beer. You can also use pH strips but they are a bit less accurate.

- Lactic acid 80% for acidifying my beer

- A density meter for measuring (residual) sugar OG and FG (see later).

- A measuring glass for density measurement

- Hop bags or a hop spider

- A bottling bucket with a filling pipe

- Carbonation drops of sugar for refermentation in the bottle

- Bottles

- Bottle tower

- Crown caps

- Crown capper

Hygiene is an asset in the brewing room

Now ... brewhouse ??? . Beer brewing is often done by hobby brewers in a garage, garden shed or hobby room / mancave. The fact is that everything that comes into contact with your grain, wort or beer must be clean and sterile. If you clean your equipment properly after a brew day and store it properly, you will really save a lot of time. Sticky or brewing equipment with residue from previous brewing days means an unpleasant start to your brew day. On my brew day I have a number of weapons against unwanted visitors from molds or organisms that are harmful.

A large tub, basin, bucket, ... with water and soap to make beer

If you have cleaned well with Enzybrew on the previous brewing day, you will not need this water and soap that often. This enzymatic cleaning product (Enzybrew) cleans and breaks down the organic dirt after brewing beer, such as vegetable fibers, proteins and starch. But still, I sometimes see a lump on a grid of my brew kettle or something does not feel 100% clean. Then I clean thoroughly again with a dishwashing brush. Do not use soap with a penetrating perfume. A mild hand soap is ideal. A cleaning tub of 30-40 liters is ideal.

A large tub, basin, bucket, ... with water and a disinfectant with active oxygen

In this disinfection tub (also 30-40 liters) all cleaned equipment that comes into contact with your grain, wort and/or beer comes. I use Puro Oxi or Chemi Oxi pro in this water. These are products in powder form that dissolve quickly and that disinfect the equipment for brewing beer. There are more aggressive products that disinfect even more thoroughly, but to clean equipment that is new or that has been thoroughly cleaned after the previous brew, these 'oxi-products' are sufficient. The disinfecting component in these products is 'active oxygen', the good news is that you do not have to rinse and everything can be used immediately. While you are preparing everything else, you can immediately put all the equipment in the bath. After about 5 minutes everything is disinfected.

A hydrogen peroxide based aerosol or an alcohol based disinfectant product.

These aerosols allow you to clean less easily accessible places. For example taps or larger fermentation vessels. I use hydrogen peroxide 'P3-oxydes rapid', you don't have to rinse here either. The alcohol-based product also works well but I don't want any alcohol in my brew that doesn't come from my grains. Something that is probably in my head :)

And when you have cleaned and disinfected all the equipment, our brewing day can begin ;)

Step 1 in brewing beer: Choosing your beer style and composing your brewing recipe.

Malt kits, beer recipes and software for making beer

What beer do you want to brew? For the first 9 beers I brewed, I used malt kits. No concentrates or extracts but a composition of malted or unmalted grains, sometimes sugar, hops, yeast and possible additives such as coriander seed. The malt kits take away some of the stress of choosing in step 1. You buy a malt kit 'Saison' (a beer style with a low alcohol percentage that has a dry, refreshing and funky taste) and that guarantees you that you have the right balance in your ingredients. This way, as a starting brewer, you can concentrate on the brewing process and the margin for error is already somewhat smaller. Think of it as the small wheels on the side of a child's bicycle. They teach you as a toddler to look, pedal, brake ... without hitting the asphalt after three meters.

Malt packages take away the stress of choosing

As a starting brewer, I choose a malt kit because with that composition in the kit I can focus on 'making beer'. That composition is made by someone with a lot of experience. A mistake in your grain composition can cause flooding during brewing, a poor yield of the sugar extraction, bland flavors or just too bitter, ... I have decided to make a composition myself after 10 brewing days with malt kits. That experience gives me confidence and automatisms, which means I will make fewer mistakes.

Brewing apps are really handy for building your own recipes

You can also find lots of recipes online and there are even a lot of apps and software where you can find shared recipes. Some apps also help you to compose your own beer recipe. For example, I use the app 'Brewfather' to compose my recipes. You don't want to throw your first 4 x 20 liters of beer down the drain because your recipe doesn't make sense. Or worse, drink and share beer that doesn't taste good at all. In Brewfather you can start from a beer style and add your personal touches within the guidelines of the recipe. I once brewed a Belgian white beer but added 4 liters of raspberry juice to the boil (raspberries were juiced with a steam extractor).

If you decide to start with a malt kit like me that includes all the well-considered ingredients, you can skip the next chapter and go straight to Step 2 (but I would definitely read Step 1 too :) .

Making a Brewing Recipe Yourself - What are the 4 Main Ingredients for Making Beer?

Before we go to step 2, I am obligated to explain the basic ingredients of beer to you. Otherwise, we can't start brewing. But I promise, I'll keep it short.

Water - makes up 95% of your beer

In these modern times we all have access to purified and safe water. It wasn’t always like this. In the past, making beer was a necessity to make the water clean. The beer wasn’t as strong as we drink it today.

You can brew beer with regular tap water or store-bought spring water if you find that valuable or if you don't have access to clean water. I've always used tap water. Some brewers look at the composition of tap water and then adjust it. There's hard water and soft water. That has to do with the amount of minerals in the water. Hard water is more suitable for strong beers like pilsner. If you want to brew a stout (a very dark beer style), you're better off brewing with soft water. But if you want to get acquainted with brewing beer, you can just use tap water. There will be an article later about what adjustments you can make to your tap water.

Malt - the basis for sugars and beer flavor

Malting grains is pure fraud

Malting is a verb in which we convert a grain into malt. Here it is important that we deceive the plant. The grain, usually barley, which is actually just a seed of a plant. The grain is brought to the same temperature and humidity as if it would germinate in nature and grow into a beautiful proud barley, oat or rye plant. At that moment the seed grain (the grain) prepares itself for the growth of a baby plant and the grain grain produces, as it were, the mother's milk (sugar) for the plant.

And then they say in the malt house: 'Just kidding, you're not going to be a plant, you're going to be beer! We're going to extract your mother's milk from the grain and you're going to be Rochefort 8". Making beer is a cruel job :) The malted grains are chock full of mother's milk that we can extract from the grains. I can write a lot about amino acids and enzymes and carbohydrates but you really don't need to know that. That mother's milk will give us sugar in the wort that we can ferment into beer with alcohol. The malted grain itself will also give a lot of flavor to your beer. Different types of malt will give a different flavor to your beer.

What types of malt are there?

A malty taste reminds of fresh bread, caramel or coffee. What is important to know is that the malted grains or malt must be dried again in time. If not, the grains will continue to germinate into plants and that is not the intention. When the malt is dry, it is sometimes also roasted or roasted. The extent to which the malt is heated or roasted will determine the color of your beer. The color of malt is expressed in EBC (European Brewery Convention), which is an international standard for the color of malt. Each malt gives a different property to your beer. Depending on the duration and temperature of roasting, we can classify the malts as follows:

Base malts

These are pale malts that you can use 60 to 100% in your beer. Even if you brew black beer (a chocolate minty stout for example), you will still use 60% pilsner malt in your beer brewing recipe. Later there will be an extensive article about malt, grain and other ingredients of beer.

- Pilsner malt: 2.5 - 4.5 EBC

- Pale Ale malt : 4 - 7 EBC

- Vienna malt: 7 - 10 EBC

- Munich malt : 15 - 25 EBC

Special malts

- Caramel or crystal malt: 5 - 450 EBC (up to 10%)

- Amber : 50 (up to 10%)

- Biscuit: 500 (up to 10%)

- Chocolate malt: 800 (up to 5%, only for Stout 8-10%)

- Roasted malt: 1400 (up to 3%, only for Stout up to 5%)

Malts from other grains (can also be considered as base malt or if heated or roasted as specialty malt)

- Wheat malt: (up to 60%)

- Rye malt: (5 to 20%)

Unmalted grains and other ingredients in beer

- Barley flakes: (up to 10%)

- Oat flakes: (up to 20%)

- Wheat flakes: (up to 5 - 10%)

- corn flakes : (up to 30%)

- Rice hulls: (to prevent your grain bed from closing, see later) (up to 5%)

When you see all these types of grains and ingredients you understand why the rows of beer bottles in the liquor store are so long and richly filled. As mentioned, you can already determine a lot of the style in your beer with the grains. But in the next paragraph another building block comes into play. And then we have another very important ingredient: Hops ...

Hops in beer: For keeping power, foam, bitterness and aroma

Hops are, along with water, malt and yeast, one of the four essential ingredients of beer. Without hops, there is no beer. Hops are the flowers of a plant called Humulus lupulus. The wonderfully fragrant hop flowers help keep your beer fresh for longer and help beer retain its head. In addition, hop flowers give your beer a natural "hoppy" aroma, flavour and bitterness. Hops can be added to beer as dried hop flowers (usually vacuum-pressed in the trade) or as hop pellets (hops that have been ground and pressed into pellets).

The hop plant belongs to the Cannabinaceae family, which also happens to include Cannabis (hemp and marijuana). Hops are hardy plants and are grown all over the world. Every beer on the market today contains hops. If it didn't, it would be a "gruit," which is essentially a beer that uses witch's brew-like herbs like bog myrtle, yarrow , heather, or juniper instead of hops.

As an aside, bitterness in beer can also come from fruits, herbs, and even vegetables that are added to the beer. For example: orange peel pith, fir tips, juniper berries, and more.

Two uses of Humulus lupulus or hops in beer

The uses of hops are divided into two very general groups: bittering hops and aroma hops. Bitter hops have a higher alpha acid content, making them more beneficial for bittering beer (a small amount goes a long way). Aroma hops will have more essential oils. It is these highly volatile essential oils that contribute to what people understand as “hoppy.” We are talking about aromas such as citrus, pine, mango, resin, melon, and more.

By adding hops early in the brewing process, all of these essential oils volatilize (boil away) either during the boil or during fermentation. This is why adding hops later in the brewing process (usually 5 minutes before the end of the boil) tends to make the beer smell "hoppier." This volatility is also why the aroma and flavor of heavily hopped beers do not hold up as well over time. Much of the hop aroma and flavor will dissipate, leaving a very different beer than the brewer intended.

Hops use varies greatly depending on the beer and what the brewer is looking for. And it is this variety of uses that makes hops such a wonderful and versatile ingredient to brew with. We will delve deeper into this later in this article, and I will also talk about dry hopping and wet hopping.

Beer Yeasts: The Greedy Monsters That Turn Wort Into Beer

Yeasts are living organisms—single-celled fungi, to be exact. Most beers use a strain of yeast called Saccharomyces, which is Latin for “sugar fungus.” Which is fitting, since the yeast that goes into beer loves sugar. Within that genus, there are two specific types of Saccharomyces yeast that are most commonly used: pilsner yeast and ale yeast.

Top-fermenting and bottom-fermenting yeasts

Saccharomyces cerevisiae is a top-fermenting ale yeast, and likely the yeast that brewers accidentally brewed with over 3,000 years ago. By top-fermenting we mean that the yeast likes to rise to the top of the beer as it feeds (and creates alcohol, carbonation, etc.). Top-fermenting ale yeast also ferments best at higher temperatures, with most preferring temperatures between 50°F and 70F (10°C to 21CF) - some 'Saison' yeasts can reach 90 degrees at the peak of fermentation. These top-fermenting ale yeasts are used to make beer styles such as wheat beers, stouts, ambers, tripels, saisons, IPAs, and many more.

Saccharomyces pastorianus is a bottom-fermenting pilsner yeast. This type of yeast was discovered and cultivated by Bavarian brewers just over 200 years ago.